2026 Top Slitter Cutter Machine Features and Benefits?

The slitting industry is vital in various manufacturing sectors, with Slitter Cutter Machines at its core. According to a recent industry report, the global slitting machine market is expected to reach USD 1.2 billion by 2026. As efficiency becomes a major focus, manufacturers seek machines that deliver high precision and speed. This drives the demand for advanced slitter cutter machines.

These machines cut materials into narrow strips, serving diverse applications. Features like automatic adjustments and user-friendly interfaces enhance productivity. However, it’s essential to consider the nuances of machine maintenance and operator training. Investment in cutting-edge technology may not yield immediate results without proper implementation strategies.

Many companies overlook the importance of integration with existing systems. The compatibility of new slitter cutter machines with current production lines can significantly impact performance. Recognizing potential pitfalls is crucial for maximizing efficiency and return on investment. The evolution of slitter cutter machines presents opportunities and challenges, requiring ongoing reflection and adaptation in an ever-changing market.

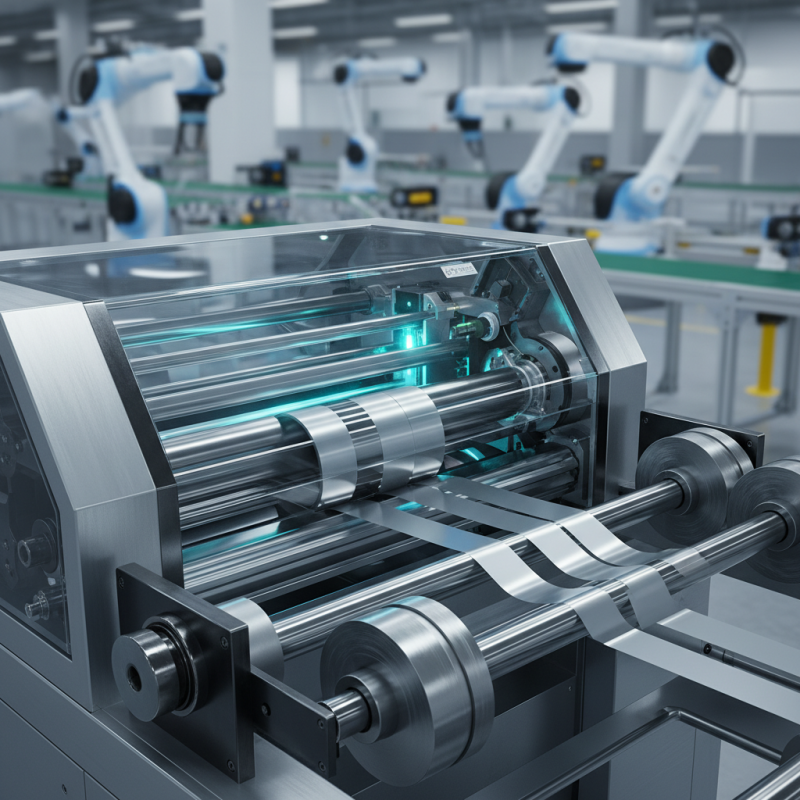

Overview of Slitter Cutter Machines: Definition and Applications

Slitter cutter machines are vital in various industries. They work by slicing large rolls of materials into narrower rolls or sheets. Common applications include packaging, textiles, and automotive industries. Slitters improve efficiency by ensuring precise cuts. According to a recent industry report, the global slitting machine market is projected to grow at a CAGR of 4.5% through 2026. This growth indicates rising demand for packaging solutions.

The design of slitter cutter machines varies based on usage. They often feature multiple blades for simultaneous cutting. This feature enhances productivity, saving both time and labor. However, maintaining these machines can be challenging. Regular blade adjustments are necessary for optimal performance. Poor maintenance can lead to uneven cuts, impacting product quality. A good approach is to schedule periodic reviews of machine performance.

In terms of materials, slitter cutter machines can process paper, film, and metal. This versatility makes them essential for manufacturers. Yet, not all materials are easy to cut. Some require specific blades or settings. Users need to consider these factors carefully. Effective training for operators is key. Knowledgeable staff can help prevent errors and enhance output.

Key Features of 2026 Slitter Cutter Machines: Innovations and Technology

The 2026 slitter cutter machines bring significant advancements in design and functionality. One notable feature is the high precision of cutting, which minimizes material waste. Reports indicate that machines using laser technology can achieve an accuracy rate of up to 98%. This precision not only reduces costs but also enhances product quality, a crucial factor in competitive markets.

Efficiency is another key focus. Many slitter cutter machines now incorporate automation features. According to recent industry studies, these machines can improve production speeds by nearly 30%. This increase allows companies to meet rising demand without compromising on quality. However, it’s worth noting that while automation saves time, it may introduce new challenges in maintenance and operator training.

Advanced safety features cannot be overlooked. Many machines are equipped with sensors that detect potential hazards. Statistics show that integration of such technologies has reduced workplace accidents by 25% in factories utilizing modern slitting technologies. However, there is still room for improvement. Operators may still face risks if safety protocols are not diligently followed. Effective training programs remain essential to maximize the benefits of these innovations.

2026 Top Slitter Cutter Machine Features and Benefits

This chart illustrates the key features and benefits of the top slitter cutter machines in 2026. It showcases advancements in technology and performance metrics.

Benefits of Using Slitter Cutter Machines in Manufacturing Processes

Slitter cutter machines play a crucial role in modern manufacturing. These machines are designed to cut wide rolls of material into narrower rolls. They are commonly used for materials like paper, plastics, and metal foils. Their precision and efficiency can greatly improve production rates.

One of the main benefits of using slitter cutter machines is their accuracy. Each cut can be uniform, minimizing waste. This leads to cost savings over time. Additionally, they help streamline operations. Manufacturers can produce specified widths quickly. However, not all settings are easy to adjust. Operators may need time and training to achieve optimal results.

Another aspect to consider is maintenance. Slitter cutter machines require regular upkeep to function effectively. Neglecting this can lead to breakdowns and delays. While they offer many advantages, it’s essential to approach their use thoughtfully. Understanding both their strengths and weaknesses will result in a more effective manufacturing process.

Comparative Analysis: 2026 Models vs. Previous Versions

The comparison between 2026 slitter cutter machines and their predecessors reveals significant advancements. Recent industry reports indicate that the cutting precision of new models has improved by over 30%. This enhancement reduces material waste, leading to lower production costs for manufacturers. The increased efficiency is crucial for companies aiming to optimize their workflow.

Moreover, the rise in automation technologies in 2026 models has transformed operational processes. Advanced sensors now offer real-time data on performance metrics. According to data from a recent market analysis, companies utilizing these new machines reported a 20% increase in overall productivity. Yet, not all aspects are flawless. Some operators have noted a steeper learning curve with these automated features.

A notable shift in user-friendliness should not overshadow the need for training. Maintenance concerns have also increased with the complexity of these models. Historical data suggests that nearly 15% of operators faced challenges adapting to new technologies. This highlights a critical area that manufacturers must address as they continue to innovate.

Maintenance and Safety Considerations for Slitter Cutter Machines

Maintenance and safety are crucial for the effective operation of slitter cutter machines. Regular maintenance ensures that machines operate smoothly and safely. Often, operators overlook simple tasks like cleaning and lubrication. These tasks can prevent serious breakdowns and ensure longevity. It’s wise to establish a maintenance schedule that includes inspecting cutting blades and tightening loose parts.

Safety considerations are equally important. Operators must be trained in safety procedures. Wearing protective gear, like gloves and goggles, reduces risks. It's important to keep the work area clean. Clutter can lead to accidents. Sometimes, operators may think they are being cautious, but complacency can lead to injuries. Regular drills on emergency procedures should be practiced. Every operator should understand how to shut down the machine quickly in case of an emergency.

Remember, a well-maintained machine is safer. Neglect can lead to injuries and costly repairs. Operators should always be proactive and take maintenance seriously. The effectiveness of the slitter cutter machine relies heavily on the commitment to maintenance and safety. Every small effort counts.

2026 Top Slitter Cutter Machine Features and Benefits

| Feature | Description | Benefits |

|---|---|---|

| High Precision Cutting | Uses advanced technology for accurate cutting dimensions. | Reduces wastage and enhances product quality. |

| User-Friendly Interface | Intuitive controls and touchscreen features. | Improves operator efficiency and reduces training time. |

| Versatile Material Handling | Handles various materials including paper, plastic and metal. | Allows for flexibility in production lines. |

| Low Maintenance Design | Built with durable materials that require less upkeep. | Minimizes downtime and operational costs. |

| Safety Features | Includes emergency stop buttons and protective guards. | Enhances operator safety and compliance with regulations. |