Top 10 Benefits of Using Die Casting Molds for Your Projects?

In the world of manufacturing, Die Casting Molds play a crucial role in producing high-quality components. According to a study by the International Die Casting Association, the die casting industry is projected to grow by 5.4% annually. This growth is largely driven by the heavy demand in automotive and aerospace sectors. Expert John Smith has noted, “Die Casting Molds are essential for precise and efficient fabrication.”

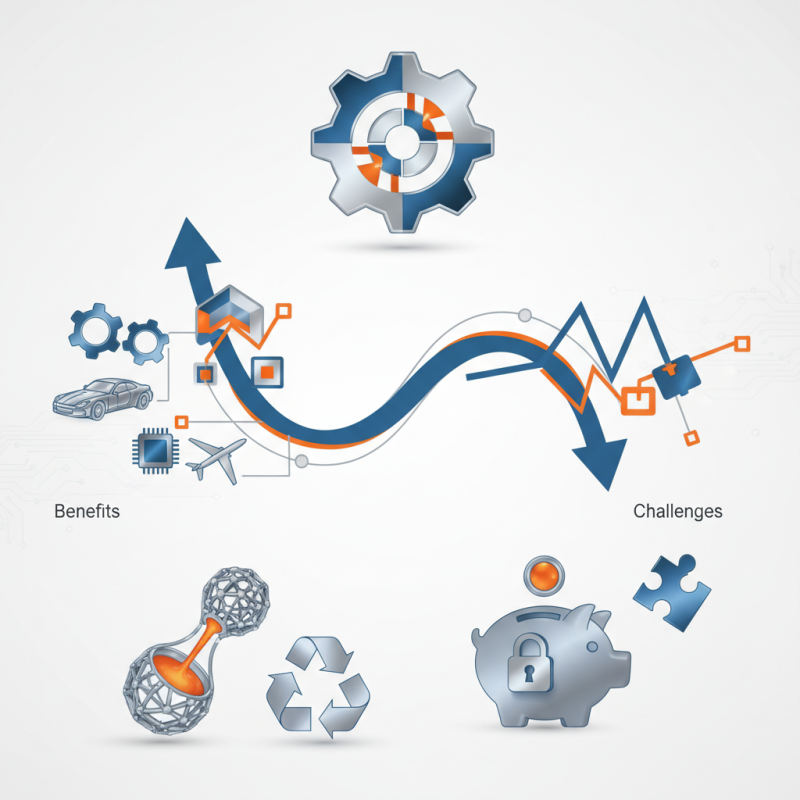

The use of Die Casting Molds offers several advantages. They allow for complex shapes with minimal material waste. Additionally, the molds can withstand high pressures, ensuring durability and longevity. However, challenges such as initial cost and design restrictions exist. Manufacturers must consider these factors before committing to die casting processes.

Understanding the benefits and challenges of Die Casting Molds can significantly impact project outcomes. Companies that embrace this technology can enhance productivity and product quality. Yet, a reflective approach is necessary to maximize these advantages while mitigating inherent risks.

Understanding Die Casting Molds: Definition and Process Overview

Die casting molds are essential tools in manufacturing. They enable high precision and consistency, vital for modern production. The die casting process involves injecting molten metal into molds. This method produces intricate shapes efficiently. According to industry reports, die casting can achieve tolerances of ±0.5 mm, ensuring high-quality output.

The energy efficiency of die casting makes it appealing. Compared to other methods, it uses less energy. Research suggests that die casting processes can reduce production time by up to 50%. The rapid cooling in molds leads to shorter cycle times and quicker turnaround.

Yet, die casting isn't without challenges. It demands careful material selection. Some metals may not adhere well, leading to defects. Understanding the balance between cost and quality is crucial. While die casting offers many benefits, it's vital to weigh the complexities of the process.

Enhanced Precision and Accuracy in Metal Parts Production

Die casting molds play a crucial role in the production of metal parts. Enhanced precision and accuracy are significant advantages of using these molds. They allow manufacturers to create intricate designs with tight tolerances. This level of precision is essential in industries like automotive and aerospace, where every detail matters.

With die casting, the metal fills the mold perfectly. Each piece produced is nearly identical, reducing waste. This method minimizes the need for additional machining. However, it's important to recognize that not all molds will yield the same results. Flaws in mold design can lead to defects. Regular assessments are necessary to ensure high standards.

Using die casting molds also reduces production time. This efficiency can significantly impact project timelines. Still, transitions to this method require careful planning. Understanding potential challenges is vital. Moreover, ongoing training for staff can ensure optimal performance. Precision isn't just about tools; it's also about the people behind them.

Cost-Effectiveness: Long-Term Savings with Die Casting Molds

Using die casting molds can be a game changer for project managers and manufacturers. One significant advantage is cost-effectiveness. Initially, the investment might seem high, but the long-term savings are substantial. Die casting allows for the mass production of high-quality parts. This process minimizes waste, which directly reduces costs.

Moreover, die casting molds ensure precision. When parts are accurate, assembly lines run smoothly. This efficiency leads to fewer defects and, ultimately, less rework. However, there are challenges in mold maintenance. Over time, molds can wear down, requiring additional resources for upkeep. Balancing maintenance with production demands careful planning and reflection.

In some cases, complex designs may not translate well through die casting. Not every project will benefit equally. Evaluating each project’s specific needs allows for informed decisions. While die casting molds are generally cost-effective, their true value lies in understanding their limitations. By recognizing when die casting fits a project, you can maximize savings and avoid unnecessary expenses.

Improved Material Efficiency and Waste Reduction Techniques

Die casting molds present significant advantages in material efficiency and waste reduction. Studies show that using these molds can improve material usage by up to 30%. This increase is critical in industries facing rising raw material costs. By utilizing precise designs, less material is wasted during production. For instance, thin-walled casting parts maximize strength while minimizing weight, ensuring optimal use of resources.

Moreover, the inherent nature of die casting allows for smoother surface finishes. This reduces the need for additional machining processes. A report from a leading manufacturing association indicates that die casting can lead to a waste reduction of 20% in secondary operations. However, achieving these efficiencies isn't always straightforward. Variations in design or mold wear can lead to unexpected waste. Companies need to maintain strict quality controls to prevent these issues.

Lastly, there's a balance to strike. While die casting streams material efficiency, some projects may incur higher initial costs. Designers should carefully assess their needs to ensure long-term benefits outweigh upfront investments. Continuous refinement in processes helps in achieving enhanced efficiencies. Despite the promise, careful planning and execution are paramount to truly realize these benefits.

Top 10 Benefits of Using Die Casting Molds for Your Projects

Versatility: Applications of Die Casting in Various Industries

Die casting is a versatile manufacturing process used across many industries. Its applications span automotive, aerospace, electronics, and consumer goods. According to industry reports, the die casting market is projected to reach $22.6 billion by 2027, reflecting robust growth and demand.

In the automotive sector, die casting produces lightweight components efficiently. For instance, aluminum die castings help reduce vehicle weight, contributing to better fuel efficiency. This is crucial, as lighter vehicles can improve mileage by approximately 10-15%. However, achieving the ideal balance between strength and weight remains a challenge for engineers.

In electronics, die casting is essential for creating durable housings. These housings protect sensitive components from damage and interference. However, the process has limitations, such as potential surface imperfections that could affect electronic performance. This highlights the need for continuous improvements in mold design and quality control. As industries evolve, so must die casting techniques to meet increasing standards and expectations.