What is the Best Damper Actuator for 2026 Applications?

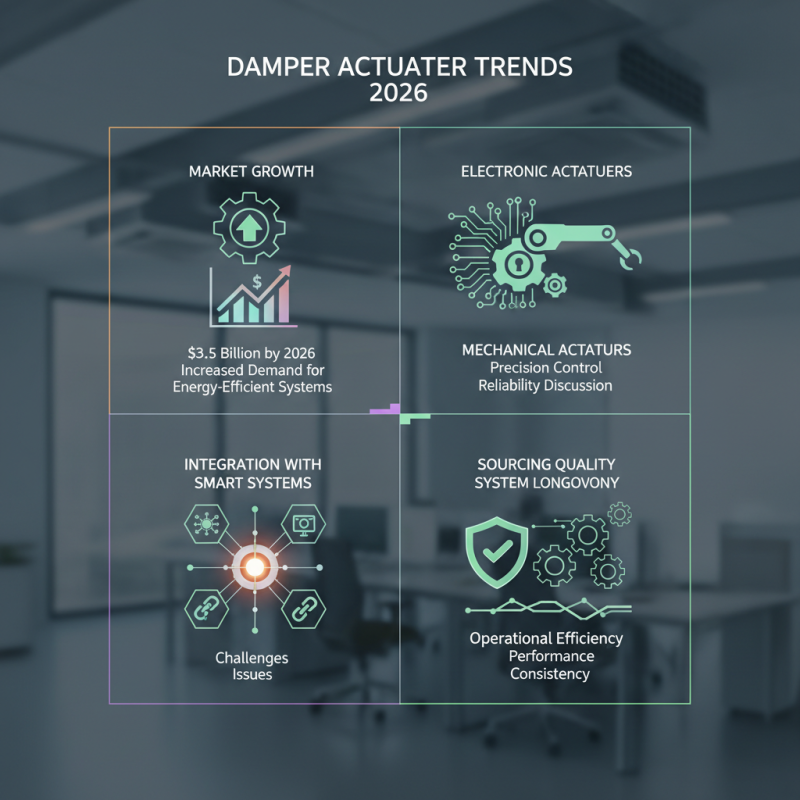

In the rapidly evolving landscape of HVAC systems, the choice of a proper Damper Actuator is critical. According to a recent report by MarketsandMarkets, the global damper actuator market is projected to reach $3.5 billion by 2026, driven by increased demand for energy-efficient systems. This highlights the importance of selecting the best damper actuator to meet the specific needs of various applications.

The effectiveness of a damper actuator depends on its responsiveness, durability, and efficiency. For instance, electronic actuators are gaining traction due to their precision and control. However, the reliability of mechanical actuators remains a point of discussion. As industries push for innovation, some actuation technologies face challenges in integration with smart systems. This necessitates careful evaluation from engineers and system designers.

Additionally, sourcing quality damper actuators can sometimes be overlooked. A well-performing actuator not only supports operational efficiency but also ensures system longevity. Yet, many companies struggle with compatibility issues and performance inconsistencies. As we approach 2026, it is essential to navigate these complexities to select the optimal damper actuator for future applications.

Current Trends in Damper Actuator Technology for 2026

As we move toward 2026, damper actuator technology is evolving. The industry is focusing on energy efficiency. This shift is crucial for sustainability. Many new designs prioritize lower power consumption. The integration of smart technology is rising, allowing for precise control. Sensor feedback mechanisms are becoming standard features. These enhance responsiveness to environmental changes.

Another trend is the shift towards compact designs. Smaller actuators can fit in tighter spaces. This creates opportunities for innovative applications in architecture. Additionally, the use of advanced materials is noticeable. Lightweight composites are being explored to reduce overall weight. However, with these advancements come challenges. Manufacturers must ensure reliability while maintaining performance.

Sustainability also drives a need for recyclable materials. This consideration adds complexity to actuator design. Balancing durability and eco-friendliness is essential. Collaborative efforts within the industry may foster breakthroughs. As we look forward, rethinking old designs is necessary. The future of damper actuators is promising yet requires ongoing reflection.

Key Specifications to Consider for Optimal Damper Actuators

When selecting a dampers actuator for 2026 applications, several key specifications must be considered. One of the primary aspects is torque. A report by the International Society of Automation mentions that an optimal actuator requires a torque range of 40-200 Nm. This range ensures that the actuator can handle varying airflow rates effectively, crucial for energy efficiency in HVAC systems.

Another critical aspect is speed. The optimal response time for a damper actuator should be between 2 to 5 seconds, as indicated by the American Society of Heating, Refrigerating and Air-Conditioning Engineers. This speed facilitates quick adjustments, enhancing system performance during dynamic changes in demand. Some actuators may lag, creating inefficiencies that could escalate operational costs.

Additionally, durability must not be overlooked. Actuators should withstand conditions like humidity and temperature fluctuations. According to the International Electrotechnical Commission, a lifespan of 20,000 cycles is preferable. Many actuators fall short of this benchmark, leading to premature failures. Considerations such as these are crucial for making informed decisions, ensuring the system performs optimally.

Comparative Analysis of Leading Damper Actuator Brands for 2026

As the demand for efficient HVAC systems grows, selecting the right damper actuator becomes crucial for 2026 applications. Users should consider energy efficiency and reliability. Advanced features, such as feedback mechanisms, can improve control and performance. However, not all brands live up to their claims. Real-world testing often reveals issues not highlighted in promotional materials.

When comparing leading brands, functionality varies. Some actuators excel in quick response times, while others may lack durability. Performance metrics like torque, speed, and noise levels are critical. Users report uneven responses in specific applications, indicating a need for careful consideration. Availability of replacement parts and warranty options is also important.

Ultimately, understanding the unique requirements of each project is essential. What works for one application may not suit another. Engaging with peers in the industry can provide invaluable insights. Always question the marketing hype and dig deeper into practical performance. Selecting a damper actuator for 2026 demands a balanced view of innovation and proven reliability.

Future-proofing Your System: Compatibility Challenges and Solutions

As we shift towards 2026, compatibility challenges will arise in choosing the best damper actuators. Future-proofing is crucial. A significant report states that 70% of systems face compatibility issues within five years of installation. Adopting a forward-thinking approach can mitigate this risk. Investing in flexible actuator designs is essential for integration with existing systems.

Older technologies may not communicate effectively with new systems. A recent industry survey found that 60% of users experience difficulties during upgrades. This indicates a pressing need for universal solutions. Manufacturers should prioritize multi-protocol support in actuator designs. This will ensure seamless integration, regardless of system age.

Tip: Assess your current system's compatibility before making a purchase. This proactive measure can save time and resources. Additionally, consider a modular approach. Modularity can allow for easier upgrades and maintenance. Embrace the challenge of ensuring long-term functionality in your systems. The right decisions now will pay off in the future.

Impact of Industry Standards on Damper Actuator Selection in 2026

The selection of damper actuators in 2026 will be heavily influenced by evolving industry standards. Recent reports indicate that around 75% of companies prioritize compliance with safety and performance regulations. This growing emphasis on standards drives manufacturers to innovate. New designs must meet rigorous specifications, which can affect their cost and availability.

In 2026, energy efficiency will be paramount. A study from the Energy Management Association found that up to 40% of energy waste comes from poorly functioning damper systems. Thus, the choice of actuators must reflect this need for efficiency. Many firms are also leaning towards smart technologies. These allow for real-time monitoring and adjustment. Yet, integrating such features often elevates initial costs.

There remain concerns about standardization. Not all suppliers adapt at the same pace. This lag can lead to compatibility issues and increased maintenance costs. Firms might face difficult decisions balancing cost, efficiency, and compliance. As these factors intertwine, the best damper actuator may vary significantly from one application to another.