What is Center Bearing and Why is it Important?

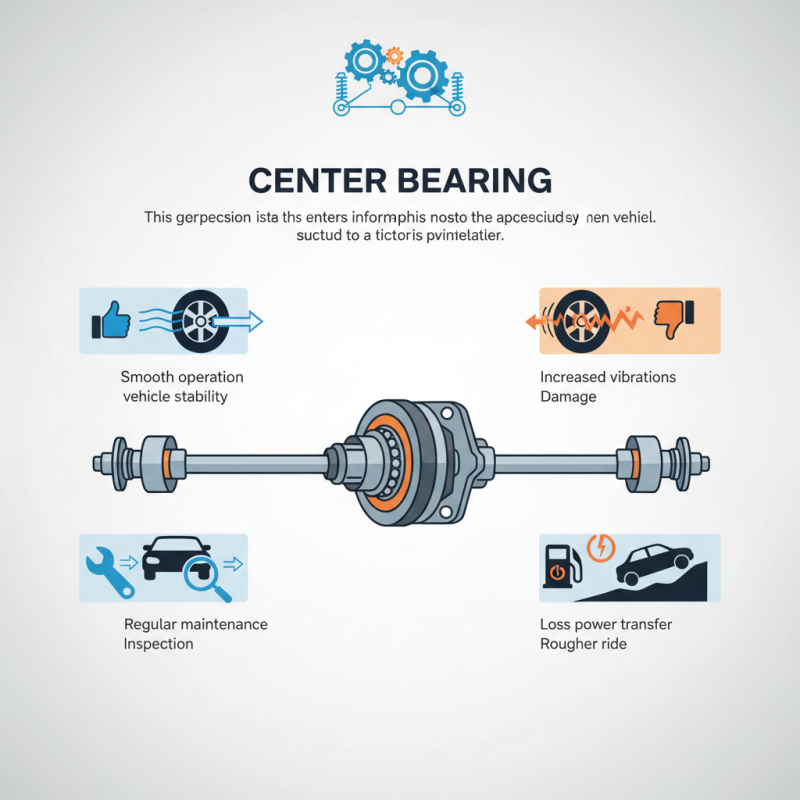

The Center Bearing plays a crucial role in vehicle stability. It is a part of the driveshaft assembly. This component supports the shaft and ensures it operates smoothly. Many drivers overlook its importance, which can lead to issues.

Without a functioning Center Bearing, vibrations can increase significantly. This might damage the driveshaft and other related parts. A failing Center Bearing can cause a loss of power transfer. It often results in a rougher ride, making driving uncomfortable.

Regular maintenance checks are vital for your vehicle's longevity. A simple inspection can save time and money in the long run. Sometimes, drivers might ignore warning signs like unusual noises. It's essential to pay attention to your car's performance and remember the importance of the Center Bearing.

Definition of Center Bearing and Its Role in Machinery

Center bearings play a crucial role in machinery by supporting rotating shafts. They provide stability and reduce friction, leading to smooth operations. Most significant industries, such as aerospace and automotive, rely on center bearings for safety and efficiency. According to a recent industry report, nearly 30% of machinery failures are linked to bearing issues.

The definition of a center bearing is straightforward. It is a type of bearing located at the center point of a shaft, supporting it during rotation. This positioning is vital. It prevents excessive vibration and misalignment, which can lead to operational failures. Data suggests that proper alignment can improve machinery lifespan by 20%. However, issues often arise due to incorrect installation or wear over time.

Regular maintenance is often overlooked. Many operators forget to check bearings until problems occur. When a center bearing fails, it can halt production. This disruption costs industries time and money. A study indicates that companies can lose up to $200,000 a day due to unexpected machinery downtimes. Awareness of center bearings is essential for operational reliability and longevity.

Types of Center Bearings and Their Specific Applications

Center bearings play a crucial role in various applications, particularly in vehicles and machinery. They ensure proper alignment and support for rotating shafts. There are different types of center bearings, each suited for specific uses.

One common type is the rubber-mounted center bearing. This design minimizes vibrations and is often used in passenger cars. It effectively dampens noise and enhances ride quality. Another type is the rigid center bearing, which provides robust support in heavy machinery. These bearings can withstand high loads without flexing.

Tips: Always inspect your center bearings regularly. Look for signs of wear or damage. A small crack can lead to bigger issues. Remember, replacement is often more cost-effective than repair, especially if performance is compromised.

Lastly, specialty bearings exist for unique applications, like those found in electric vehicles. They may have specific materials to handle different environments. Choosing the right center bearing can greatly impact your machine’s efficiency. Take time to research and choose wisely; oversights can lead to costly errors.

What is Center Bearing and Why is it Important? - Types of Center Bearings and Their Specific Applications

| Type of Center Bearing | Description | Common Applications | Importance |

|---|---|---|---|

| Single Center Bearing | Supports the driveshaft and maintains alignment during operation. | Light trucks, SUVs, passenger cars. | Reduces vibration and improves handling. |

| Double Center Bearing | Provides additional support for longer driveshafts. | Heavy-duty vehicles, long trucks. | Enhances stability and reduces drivetrain stress. |

| Rubber Center Bearing | Utilizes rubber for shock absorption and vibration dampening. | Small to medium-sized passenger vehicles. | Quiets operation and extends component lifespan. |

| Ball Bearing Center | Uses ball bearings for higher load capacity and smooth rotation. | Performance vehicles, sports cars. | Improves efficiency and increases performance. |

Key Functions and Benefits of Center Bearings in Engineering

Center bearings play a crucial role in engineering applications, particularly in rotating systems. They support rotating shafts, ensuring stability and balance. This is vital for reducing vibrations and noise. According to a 2022 industry report, improper bearing alignment can increase failures by over 30%.

The main functions of center bearings include load distribution and support. They absorb radial and axial loads, maintaining alignment between components. A well-functioning center bearing can enhance operational efficiency. Researchers estimate that effective bearing systems can increase machinery lifespan by 20%. However, many systems still overlook routine inspections, leading to costly repairs.

Reliability is another critical benefit. With the right center bearings, engineers can achieve smoother operations. Yet, data indicates that 25% of machinery failures stem from bearing issues. It’s essential to recognize that while center bearings are often easy to install, maintenance is frequently neglected. This can result in reduced performance and more downtime. Continuous attention to center bearings can make a significant impact on overall system health.

Common Issues with Center Bearings and How to Troubleshoot Them

The center bearing plays a crucial role in supporting the driveshaft of a vehicle. It's located in the middle of the driveshaft, stabilizing it during rotation. A malfunctioning center bearing can lead to vibrations, noise, and even premature wear on the entire drivetrain. According to industry reports, around 20% of drivetrain failures are linked to issues originating from the center bearing.

Common problems include wear and tear, misalignment, and lack of lubrication. Drivers may notice unusual sounds when the bearing is failing. A clicking or clunking noise often indicates that the bearing needs immediate attention. Moreover, vibration felt in the cabin can escalate quickly if not addressed. Regular inspections can identify these symptoms early, potentially saving significant repair costs.

Troubleshooting involves a few steps. Firstly, check for any visible wear on the bearing. A worn rubber mount may lead to misalignment. Inspecting lubrication is essential too. Insufficient grease can lead to overheating and eventually failure. Data suggests that addressing these issues early can extend the life of related components by up to 30%. It's clear that proactive maintenance of the center bearing is vital for a vehicle's overall health.

Best Practices for Maintaining Center Bearings for Longevity

Center bearings play a critical role in the drivetrain of many vehicles. Proper maintenance is crucial for their longevity. To ensure optimal performance, regular inspections should be conducted. Look for signs of wear, unusual noises, or vibrations when driving. These can indicate potential issues that need addressing.

Lubrication is essential for center bearings. Keep them clean and free of debris. Use the appropriate lubricant to avoid any damage. Over time, the lubricant can break down, causing friction. Regularly replacing it can significantly reduce wear. Check the condition of the mountings as well. Damaged or worn mounts can affect the alignment and lifespan of the bearing.

Keeping an eye on the overall condition of the surrounding components is also essential. If the entire system is neglected, it will reflect poorly on the center bearing's health. Maintenance routines should include checking adjacent parts for wear. It’s a simple step that can prevent bigger problems in the future. Ignoring these details could lead to costly repairs down the road. Being proactive saves time, effort, and money.