How to Choose the Best Injection Molding Machine With Robot?

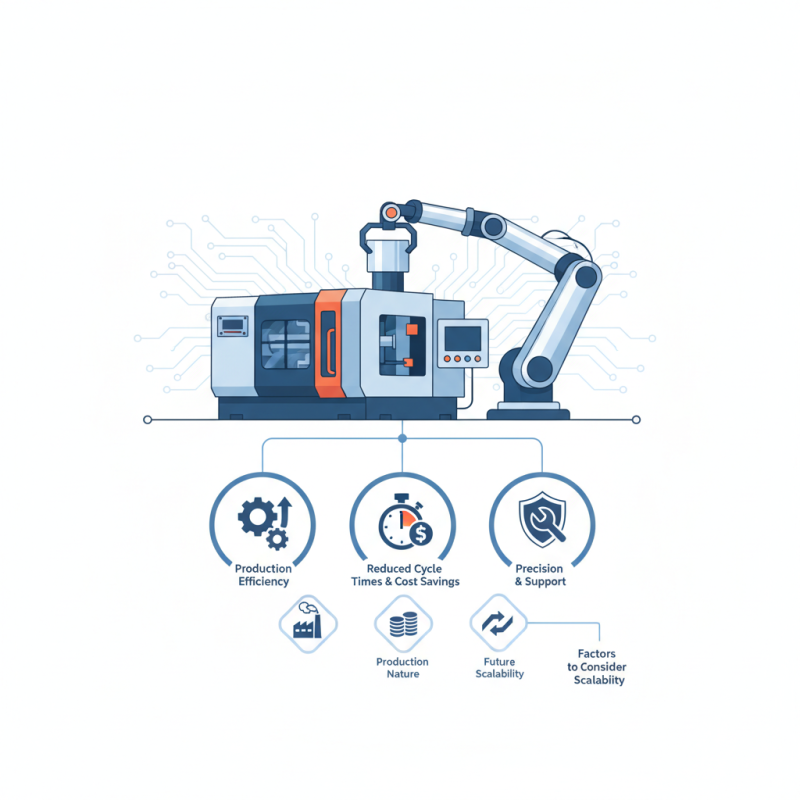

In the fast-evolving world of manufacturing, choosing the right Injection Molding Machine With Robot can greatly impact production efficiency. A recent report by MarketsandMarkets projects that the injection molding market will reach $17.5 billion by 2026. This growth underscores the importance of selecting the right equipment. Experts like Dr. Alex Moore emphasize, "Automation in injection molding is not just a trend; it’s a necessity for competitiveness."

The integration of robotics not only enhances precision but also reduces cycle times significantly. However, many manufacturers struggle with this decision. Understanding specifications, functionalities, and compatibility is essential. The wrong choice can lead to inefficiencies that cost time and money. Some companies overlook the importance of after-sales service and support, leading to complications later on.

Making a well-informed decision requires careful consideration of various factors. The nature of production, budget constraints, and future scalability all play crucial roles. If these elements are not aligned, the investment may not deliver the expected returns. A thoughtful approach in selecting your Injection Molding Machine With Robot is crucial for long-term success.

Understanding Injection Molding Machines: Features and Types

When selecting an injection molding machine, understanding its features is crucial. Injection molding machines come in various types, each serving different manufacturing needs. There are hydraulic, electric, and hybrid machines. Hydraulic machines are powerful and reliable. However, they can consume more energy compared to others. Electric machines are more efficient but may have a higher upfront cost. This balance is important to consider.

We must also think about the machine's clamping unit. It's a key feature that affects the quality of the molded parts. A robust clamping unit can prevent defects like flash or uneven thickness. The control system is another critical element. Some machines have simple interfaces while others offer advanced automation capabilities. Advanced systems may provide better precision but can be complex to operate.

Robots can enhance the process by improving efficiency. They take care of part removal and can also assist in inspection. However, integrating robots requires careful planning. Compatibility with the injection molding machine is essential. A mismatch can lead to operational headaches. Each feature affects production, so one should reflect on the trade-offs. Choosing the right machine isn’t just about specs; it also involves understanding how all parts will work together.

Assessing the Role of Robots in Injection Molding Processes

In injection molding, robots play a vital role. They enhance efficiency and precision during production. Automating the handling of parts streamlines the workflow. This reduces the chances of human error, which can be costly. Robots can work continuously without fatigue, unlike their human counterparts. This increases overall productivity and meets high demand.

However, not all robotic solutions are perfect. Choosing the right type of robot is not straightforward. Different tasks require different capabilities. A robot that excels in one area may struggle in another. Compatibility with the injection molding machine is crucial. Nevertheless, sometimes, companies invest in complex systems only to find them underperforming.

Integrating robots into injection molding can also bring challenges. Initial setup costs can be high. Workers may need additional training to adapt to new technology. Moreover, maintenance is essential to avoid downtime. Regular checks can prevent minor issues from becoming major problems. Balancing these factors is key to a successful operation.

Criteria for Selecting the Right Injection Molding Machine

Selecting the right injection molding machine is crucial for efficient production. A recent industry report indicated that over 40% of manufacturers are dissatisfied with their current machines due to production inefficiencies. The main criteria include machine size, clamp force, and material compatibility.

It's essential to consider the size of the machine. A machine that is too small may not handle large parts effectively, leading to quality issues. On the other hand, a machine that is too large can waste energy and inflate costs. Additionally, the clamp force must match the material used. For example, softer materials require less force, while harder materials need more.

**Tip:** Analyze your production demands carefully. Understanding your parts and their requirements can guide you towards the correct machine specifications.

Material compatibility is another critical factor. Using the wrong material can lead to defects. A study revealed that 30% of production issues stem from improper material selection. Ensuring the machine can process your chosen materials can save time and resources in the long run.

**Tip:** Conduct thorough testing with your intended materials. This step can prevent unforeseen challenges and streamline your production process.

Evaluating Compatibility Between Machines and Robotic Systems

When selecting an injection molding machine, compatibility with robotic systems is key. Data from recent industry reports shows that over 70% of manufacturers face challenges integrating these systems. An effective evaluation process is essential. Assess machine specifications alongside robotic capabilities. Look for seamless integration to enhance productivity.

Always consider the machine's cycle time. A mismatch here can lead to inefficiencies. For instance, if the robotic arm is faster, it may lead to idle time. This observation is crucial for maintaining operational flow. Review throughput metrics and robot payload capacities before making a decision. These parameters impact overall performance.

**Tips:** Ensure your injection molding machine supports various robotic interfaces. This flexibility can future-proof your investment. Also, consider ongoing maintenance needs. Sometimes, additional training for staff is necessary. It’s vital for robotic operations to run smoothly in tandem with molding processes. Regularly revisiting compatibility ensures long-term success.

Cost Considerations and Long-Term Benefits in Your Selection

Choosing the right injection molding machine with a robot involves careful consideration of costs and long-term benefits. Initial investments can be significant. However, evaluating cost-efficiency over time is crucial. Maintenance costs, energy usage, and operational efficiency all play a role. Some machines may appear cheaper upfront but can incur higher expenses later.

Think about productivity as well. A well-integrated robotic system can ramp up output. This can lead to faster return on investment, which is vital for many businesses. It’s important to assess how often the machine will be used. Underused machines may not justify their cost. On the other hand, overworking a budget option may lead to breakdowns and dissatisfaction.

Don’t overlook the importance of flexibility, either. A machine that adapts to various projects can save money in the long run. It's essential to reflect on your workload and future projects. What may seem perfect now could become a burden down the line. Balancing immediate needs with long-term vision is key. Investing wisely in technology should align with future goals.