What is a Motorized Valve and How Does it Work?

In the world of automated systems, the significance of a Motorized Valve cannot be overstated. Experts like Dr. Emily Hawthorne, a leading authority in fluid control systems, have noted, "Motorized Valves are the backbone of modern piping systems." These devices play a vital role in controlling fluid flow, contributing to efficiency and precision in various applications.

Motorized Valves operate by utilizing an electric actuator to open or close the valve according to a set command. They can adjust flow rates and maintain pressure levels in systems ranging from heating to industrial processes. The integration of technology has made these valves smarter, but challenges still exist. Installation errors or mechanical issues can compromise performance.

Understanding the intricacies of a Motorized Valve is essential for engineers. It involves more than just knowing how they work; it requires an awareness of their limitations. As technology evolves, ongoing learning about these components will ensure better reliability and performance in critical operations.

What is a Motorized Valve?

A motorized valve is an automated device that controls the flow of liquids or gases. Typically driven by an electric motor, it provides precise control in various applications. These valves can be found in heating systems, cooling systems, and even in large industrial processes. According to a recent industry report, the global motorized valve market is expected to reach $6.1 billion by 2026, indicating robust growth in automation solutions.

The operation of a motorized valve is straightforward. When electrical signals are received, the valve actuator moves the valve stem. This action opens or closes the valve, regulating the flow accordingly. Depending on the design, different types of motorized valves can achieve various flow rates and pressure levels. Understanding these dynamics is crucial for efficiency and optimizing system performance.

Tips: When choosing a motorized valve, consider the specific requirements of your application. Size, pressure ratings, and response time are all important factors. Regular maintenance checks can enhance the lifespan of the valve and prevent unexpected failures. Testing the operation periodically ensures that the valve performs as required under life-like conditions. Be mindful of installation requirements; they can significantly affect performance and function.

Components of a Motorized Valve

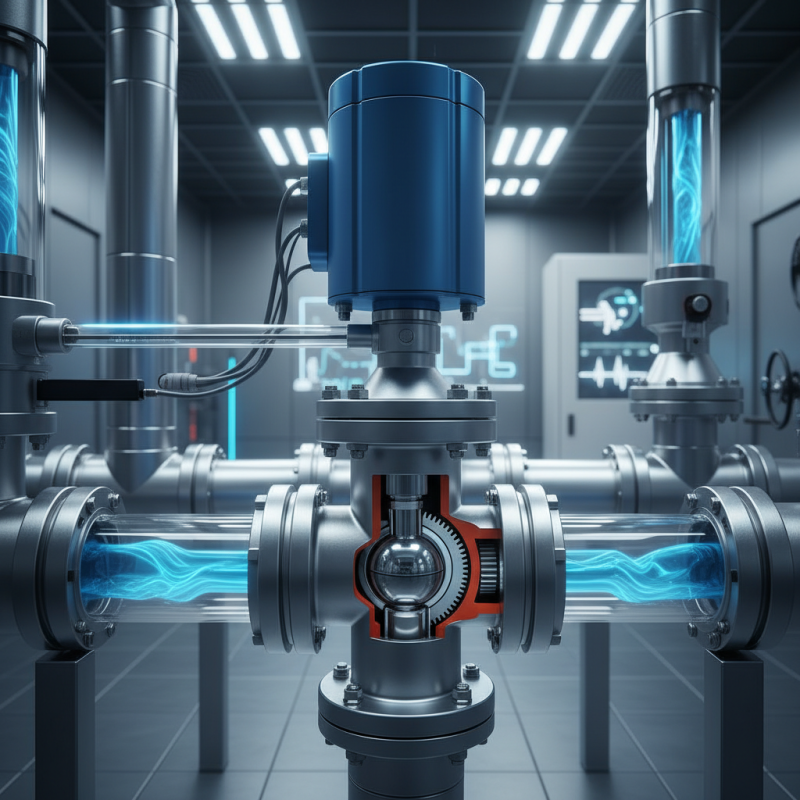

A motorized valve is a key component in control systems. Its operation relies on various parts that work together seamlessly. To understand how a motorized valve functions, we should focus on its main components.

The actuator is the heart of the motorized valve. It provides the motion needed to open or close the valve. Various types of actuators are used, such as electric, pneumatic, or hydraulic types. Each type has its pros and cons. The decision on which actuator to use depends on specific application needs. The position feedback system is vital. It informs operators about the current valve position, ensuring accurate control.

Other components include the valve body. This part is what fluid flows through. Its design can vary significantly. Some valves are straightforward, while others are complex. Seals and gaskets are essential too. They prevent leaks and ensure efficiency. However, over time, seals can wear out. This requires regular inspection and maintenance. It’s easy to overlook these details, but they are crucial for reliable operation.

How Does a Motorized Valve Operate?

A motorized valve is designed to control the flow of liquids or gases automatically. It typically involves an electric actuator that opens or closes the valve based on predetermined settings. The operation of a motorized valve involves the interplay between electric signals and mechanical movement.

When an electric signal is sent to the actuator, a motor spins, causing a gear mechanism to turn. This movement either opens or closes the valve. Sensors can provide feedback to ensure the valve is in the correct position. If installed correctly, these valves can enhance efficiency dramatically.

Tips: Always check your installation instructions carefully. Misalignment can cause leaks. Regular maintenance is essential for optimal performance. A motorized valve may fail if not properly cared for. Understand that every system has its limits.

Sometimes, troubleshooting motorized valves can be challenging. Signs of malfunction might not be immediately visible. Unexpected noises or slow operation could indicate deeper issues. Regularly monitor the system to minimize these problems. Reflections on such experiences can lead to improvements in future setups.

Applications of Motorized Valves in Various Industries

Motorized valves play a crucial role in various industries. Their primary function is to control the flow of liquids and gases. These valves are equipped with electric actuators that enable precise control. This is especially valuable in manufacturing processes. For example, in the food industry, motorized valves ensure a consistent flow of ingredients. This helps maintain product quality and safety.

In the HVAC sector, these valves regulate airflow and temperature. They enhance energy efficiency by responding to real-time demands. However, implementation can be tricky. Poor calibration may lead to inefficient system performance. In agriculture, motorized valves manage irrigation systems. They help optimize water usage. Yet, farmers often face challenges with maintenance.

Despite the advantages, motorized valves can fail unexpectedly. This can disrupt operations in critical industries. Regular inspections and testing are essential. Balancing automation with reliability is a common struggle. Ultimately, the successful application of these valves requires careful consideration. Industry professionals must address potential flaws to harness their full potential.

Advantages of Using Motorized Valves over Manual Valves

Motorized valves offer several advantages over manual valves, making them increasingly popular in various industries. These valves enable automated control of fluid flow, reducing the need for human intervention. A study by the International Society of Automation indicates that automation can improve operational efficiency by up to 30%. This efficiency often leads to lower labor costs and reduced human error.

Using motorized valves can enhance precision in control applications. Unlike manual valves, which can vary based on operator skill, motorized valves provide consistent and repeatable performance. Many facilities have reported a 20% decrease in operational errors when switching to motorized systems. This consistency is crucial in industries where exact specification adherence is essential.

However, motorized valves are not without their challenges. Initial installation costs can be higher compared to manual options. Furthermore, they require reliable power sources for operation. Regular maintenance can also be more complex due to the electronic components involved. These factors should be weighed when considering the transition to motorized valves. Balancing these pros and cons is essential for making informed decisions in system design.

What is a Motorized Valve and How Does it Work?

| Feature | Motorized Valve | Manual Valve |

|---|---|---|

| Operation Method | Automatic (electrical) | Manual (hand-operated) |

| Response Time | Fast (milliseconds) | Slower (depending on manual action) |

| Precision | High Precision | Variable Precision |

| Labor Costs | Lower (automated) | Higher (manual operation) |

| Maintenance | Requires regular checks | Flexible maintenance schedule |