Top 5 Pallet Lifter Options for Your Business Needs?

In the world of logistics and warehousing, efficiency is key. Choosing the right equipment can make all the difference. A pallet lifter stands out as a vital tool for many businesses. It elevates heavy loads easily. This equipment is essential in various sectors, from retail to manufacturing.

When selecting a pallet lifter, consider your specific business needs. There are many options available. Some models are designed for heavy lifting, while others focus on portability. The right choice affects workflow and worker safety. However, not every pallet lifter is perfect for every situation. Some may fail to meet durability expectations over time.

Ultimately, investing in a suitable pallet lifter can enhance productivity. Yet, it's important to reflect on the limitations of different models. Assessing your unique requirements is critical for making an informed decision. Balancing efficiency and functionality is a challenge, but a well-chosen pallet lifter can significantly improve your operations.

Understanding the Importance of Pallet Lifters in Business Operations

Pallet lifters are crucial for efficient business operations. They simplify the movement of heavy goods. According to industry reports, companies that utilize pallet lifters can increase productivity by over 25%. This improvement is vital in warehouses and manufacturing settings where time is money.

In addition to efficiency, safety is a primary concern. Manual lifting can lead to injuries. Studies show that more than 30% of workplace injuries result from improper lifting techniques. Pallet lifters help reduce these risks. They take on the heavy lifting tasks, allowing staff to focus on more strategic work.

However, businesses should assess their specific needs. Not all pallet lifters are suited for every job. Some may lack the capacity for larger loads. Others might not be designed for outdoor use. Understanding your operational requirements is key. Failing to choose the right equipment can lead to costly inefficiencies. It’s essential to reflect on both current needs and future growth to make an informed decision.

Key Features to Consider When Choosing a Pallet Lifter

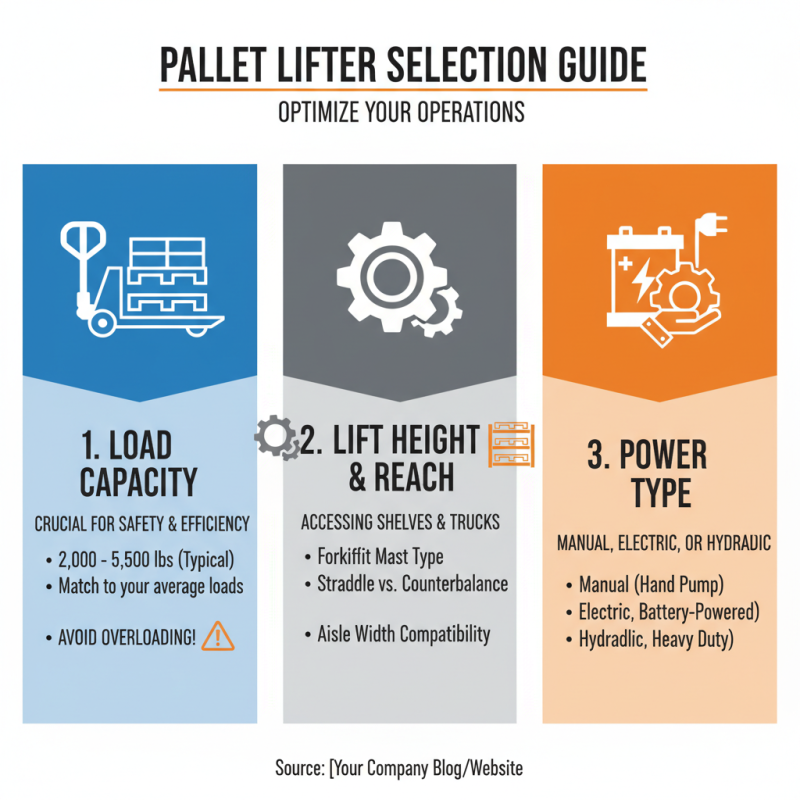

When selecting a pallet lifter, consider key features that will optimize your operations. Load capacity is crucial. Most pallet lifters can handle between 2,000 and 5,500 pounds. Knowing your typical loads helps you choose the right model. Keep in mind that overloading can damage equipment, leading to expensive repairs.

Another important feature is lift height. Many models offer a range from 3 to 7 feet. Evaluate your storage needs carefully. If your warehouse has high racks, a lifter with greater lift capability is essential. Choosing the wrong height can waste time and labor.

For better maneuverability, look for lifters with a tight turning radius. Some reports note that models with enhanced steering features improve efficiency in small spaces. Smooth steering can minimize worker fatigue. Pay attention to the design of the wheels as well. Solid rubber wheels often outperform others in durability.

Tips: Regular maintenance is key. Inspect hydraulic systems and wheels monthly. If a lifter slows down, it might need immediate attention. Train staff on proper usage to avoid mishaps. Consider ergonomics too. A poorly designed lifter can lead to injuries. Optimize both safety and productivity by making informed choices.

Comparative Analysis of the Top 5 Pallet Lifter Models

When evaluating pallet lifters, it’s vital to compare their specifications and usability. Each model offers unique features that cater to different operational requirements. Look closely at the lift capacity. Some can lift over 4,000 pounds, which benefits heavy-duty applications. Other models are lighter, suitable for smaller loads. These distinctions can significantly impact your choice.

Consider dimensions too. A compact design is crucial for tight spaces. Narrow aisles may require smaller lifters to maneuver effectively. The control options deserve attention as well. Electric lifters are more user-friendly but have a higher upfront cost. Manual options can be more economical but demand more physical effort. Reflect on your team's capabilities and preferences before deciding.

Safety features should never be overlooked. Some models come with advanced braking systems, while others may lack these essential attributes. It's essential to prioritize safety alongside efficiency. Sometimes, the most efficient option is not the safest. Balancing these factors may require some trial and error. Assess your operational environment continually to find the best fit.

Cost vs. Benefits: Evaluating Your Pallet Lifter Investment

Investing in a pallet lifter can significantly impact your business operations. It’s essential to weigh the costs against the benefits. Many companies find that the initial expenditure pays off with enhanced efficiency. A good pallet lifter can streamline loading and unloading tasks. It saves time and reduces physical strain on workers. However, some options might appear cost-effective but fall short in durability. This could lead to more frequent repairs or replacements.

When evaluating your options, consider the specific needs of your operations. Factors such as load capacity, lifting height, and ease of use are crucial. Some businesses may overlook these aspects and later regret their choices. A lifter that's too weak could hinder productivity. Conversely, opting for a heavy-duty model may exceed the necessary requirements. This can lead to wasted resources.

Beyond functionality, think about maintenance costs and available support services. A low-priced model may seem appealing at first glance. But consider the long-term implications. High maintenance can erode savings over time. Ensure you have a clear understanding before making a decision. Balancing cost with the expected benefits is the key. Your investment should align with your operational needs and growth plans.

Top 5 Pallet Lifter Options Cost vs. Benefits

Maintenance Tips for Enhancing the Longevity of Your Pallet Lifter

Maintaining your pallet lifter is crucial for its longevity and performance. Regular inspections can identify potential issues before they escalate. Check the hydraulic system for leaks. Any noticeable fluid can indicate a problem. Pay attention to the wheels as well. Worn wheels can lead to uneven lifting. Replace them when necessary. It’s better to cope with small issues than face costly repairs later.

Cleaning is often overlooked but essential. Dust and debris can gather in hard-to-reach areas. This buildup may impair functionality. Use a damp cloth to wipe down surfaces regularly. Ensure you follow up with lubricant on joints and moving parts. A little care goes a long way.

Training your staff is important for effective usage. Misuse can lead to premature wear and tear. Hold regular sessions to familiarize everyone with the equipment. Encourage them to report any concerns immediately. An ongoing communication line can help identify issues early. Small, proactive steps now can save you time and money later on.

Top 5 Pallet Lifter Options for Your Business Needs

| Model | Capacity (kg) | Weight (kg) | Lifting Height (mm) | Features |

|---|---|---|---|---|

| Manual Pallet Lifter | 1500 | 90 | 2000 | Durable, Economical, Lightweight |

| Electric Pallet Lifter | 2000 | 120 | 2500 | Efficient, User-Friendly, Rechargeable |

| Hydraulic Pallet Lifter | 1800 | 100 | 2200 | Heavy-Duty, Compact, High Stability |

| Low Profile Pallet Lifter | 1500 | 80 | 1500 | Low Height, Strong, Easy Maneuverability |

| Cold Storage Pallet Lifter | 1200 | 110 | 1800 | Corrosion Resistant, Insulated, Durable |

Maintenance Tips for Enhancing the Longevity of Your Pallet Lifter

- Regularly inspect the lifting mechanism for wear and tear.

- Keep wheels and castors free of debris to ensure smooth operation.

- Lubricate joints and wheels on a regular basis.

- Check for hydraulic fluid leaks and top up as necessary.

- Store in a dry environment to prevent rust and corrosion.

Related Posts

-

Embracing Innovation in 2025 How to Choose the Best Pallet Lifter for Your Supply Chain

-

Unlocking Efficiency: The Advantages of the Best Reach Truck for Modern Warehousing

-

8 Reasons Why a Powered Pallet Jack Is Essential for Efficient Warehouse Operations

-

Exploring the Future of Best Pallet Trucks in the 2025 Market Landscape

-

Elevating Industry Standards with the Best Pallet Stacker Innovations

-

What Makes the Best Powered Pallet Jack Stand Out in Material Handling